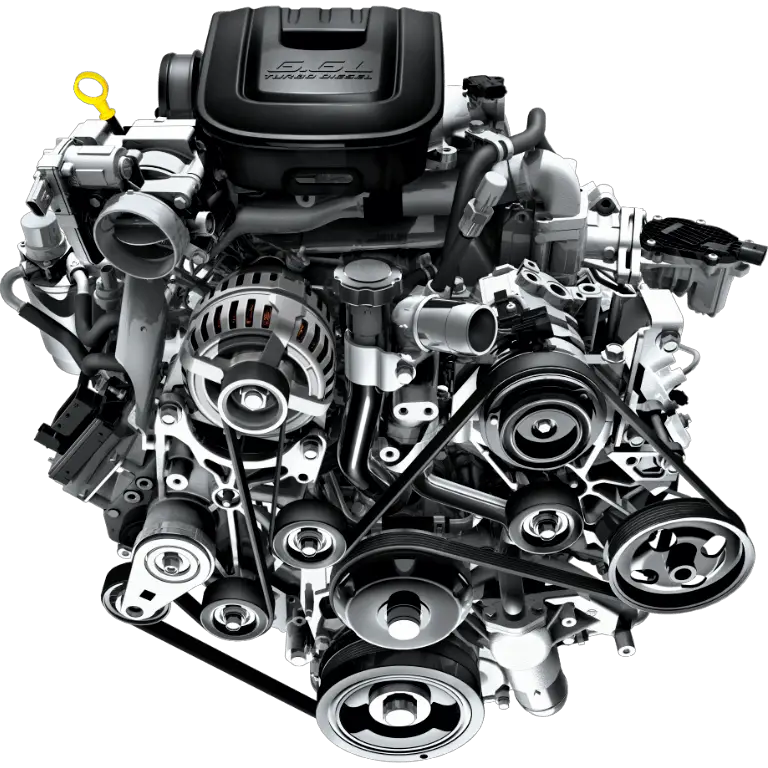

For nearly two decades, the 6.6L Duramax diesel engine has been a cornerstone of General Motors’ heavy-duty truck lineup. Found in Chevrolet Silverado and GMC Sierra HD models, this powerhouse has earned a reputation for its robust performance, impressive torque, and ability to handle heavy loads. However, like any complex machinery, the Duramax isn’t without its flaws.

Certainly! Here’s a comprehensive table summarizing the key points from the blog post about 6.6L Duramax engine problems:

| Generation | Years | Key Issues | Causes | Symptoms | Solutions | Regional Impact |

|---|---|---|---|---|---|---|

| LB7 | 2001-2004 | Injector Failures | Poor design, high-pressure cycles | Hard starts, rough idle, white smoke | Recalls, injector replacement | High downtime for contractors & farmers |

| LLY | 2004.5-2005 | Overheating, Head Gasket | Weak cooling, high EGTs | Engine overheating, coolant loss | Cooling upgrades, head studs | Severe in hot states (TX, AZ, NV) |

| LBZ & LMM | 2006-2010 | CP3 Pump & Fuel Issues | Pump failures, poor fuel quality | Power loss, hard starts, “Death Rattle” | Pump replacement, better fuel | Rural areas with varying fuel quality |

| LML | 2011-2016 | Emissions Systems | DEF, DPF, EGR, NOx sensor issues | CEL, reduced power, poor MPG | Component replacements, “deletes” | Temptation to “delete” in non-testing states |

| L5P | 2017-present | “Untunable” Engine | Encrypted ECM | No mechanical issues, but no tuning | None (by design) | Frustration in mod-heavy cultures (CO, UT) |

| Universal Issues | Affected Areas | Symptoms | Solutions | Notes |

|---|---|---|---|---|

| Allison Transmission | All generations | Shudder, harsh shifts, leaks | Fluid change, solenoid/clutch replacement | – |

| Water Pump | All, around 100k miles | Bearing failure, leaks | Replacement | – |

| Glow Plugs & Controller | All, worse in cold regions | Hard winter starts | Component replacement | Critical in states like MN |

| Cracked Pistons | LBZ especially | Catastrophic failure | Engine rebuild | Often due to aggressive tuning |

| Oil Leaks | All | Various leak locations | Gasket, line, seal replacements | Regular issue across generations |

| Preventive Measures | Purpose | Regional Relevance |

|---|---|---|

| Quality Diesel | Protect fuel system | Critical in rural areas |

| Strict Oil Changes | Maintain injectors | Universal |

| Monitor Temps | Prevent overheating | Hot climates & towing states |

| Cautious Tuning | Avoid piston damage | High-elevation areas (CO, UT) |

| Block Heaters | Aid cold starts | Northern states (MN, MI) |

| Emissions Care | Avoid limp mode | Stricter states (CA, NY) |

| Understand “Delete” Risks | Legal compliance | All states (federal law) |

Key Themes in American Duramax Culture:

- Power vs. Reliability balance

- Impact of emissions on performance

- Strong DIY repair culture

- Regional challenges shape experience

- Despite issues, valued for hard-work ethos

Lessons by Generation:

- LB7: Quality components matter

- LLY: Heat is the enemy

- LBZ/LMM: Fuel quality is key

- LML: Emissions are non-negotiable

- L5P: Sometimes, stock is best

In this comprehensive blog post, we’ll explore the most common issues plaguing various generations of the 6.6L Duramax engine, offering insights that every American truck owner should know.

A Brief History of the 6.6L Duramax

Before we dive into the problems, let’s understand the engine’s evolution:

- LB7 (2001-2004): The first-generation Duramax

- LLY (2004.5-2005): Improved with a variable geometry turbo

- LBZ (2006-2007): More power, strengthened internals

- LMM (2007.5-2010): Added DPF for emissions

- LML (2011-2016): Further emissions updates, higher output

- L5P (2017-present): Complete redesign, most powerful yet

Each generation brought improvements, but also its own set of challenges.

1. LB7 (2001-2004): Injector Issues

The inaugural Duramax had one glaring issue: faulty fuel injectors.

Causes:

- Poor injector design led to internal ball seat failures

- High-pressure cycles caused cracking

- Inadequate sealing allowed fuel dilution in engine oil

Symptoms:

- Hard starts, especially when cold

- Rough idling or surging

- White smoke from exhaust

- Reduced power and poor fuel economy

Solutions:

- GM issued multiple recalls and extended warranty to 7 years/200,000 miles

- Complete replacement with updated injectors

- Many owners opt for aftermarket injectors for better reliability

Impact on American Owners:

In a nation where work trucks are a way of life, the LB7’s injector problems hit hard. Many contractors and farmers faced downtime during critical periods, leading to financial strains.

2. LLY (2004.5-2005): Overheating and Head Gasket Failures

The LLY’s main nemesis? Heat.

Causes:

- Inadequate cooling system design

- High EGTs (Exhaust Gas Temperatures) under load

- Weak head bolts and gaskets

Symptoms:

- Engine overheating, especially when towing

- Coolant loss

- White exhaust smoke (coolant in cylinders)

- Decreased power

Solutions:

- Aftermarket cooling system upgrades (larger radiator, fan)

- Head studs replacement

- In severe cases, head gasket replacement

Impact on American Owners:

In states like Texas, Arizona, or Nevada, where temperatures soar and long-haul towing is common, LLY owners found themselves constantly monitoring gauges, afraid to push their trucks.

3. LBZ and LMM (2006-2010): CP3 Pump and Fuel Concerns

While more robust, these models faced fuel system challenges.

Causes:

- CP3 injection pump failures

- Low-quality fuel (common in rural areas)

- Clogged fuel filters

Symptoms:

- Loss of power under load

- Hard starting

- “Death Rattle” sound (catastrophic pump failure)

- Erratic performance

Solutions:

- CP3 pump replacement (OEM or aftermarket)

- Adding a lift pump for better fuel delivery

- Regular fuel filter changes

- Using higher-quality diesel fuel

Impact on American Owners:

In the heartland, where diesel quality varies greatly between major truck stops and local stations, many LBZ and LMM owners learned to be picky about their fuel sources.

4. LML (2011-2016): Emissions System Nightmares

Meeting stricter EPA standards came at a cost.

Causes:

- DEF (Diesel Exhaust Fluid) system failures

- DPF (Diesel Particulate Filter) clogging

- EGR (Exhaust Gas Recirculation) valve issues

- NOx sensor malfunctions

Symptoms:

- Check Engine Light with various codes

- Reduced power or limp mode

- Poor fuel efficiency

- Increased regen cycles

Solutions:

- Component replacements (sensors, valves)

- DPF cleaning or replacement

- Some owners choose to delete emissions systems (illegal for on-road use)

Impact on American Owners:

For many, especially in states with no emissions testing like Florida or Michigan, the temptation to “delete” was strong. However, with federal crackdowns, most now grudgingly maintain these systems, impacting both wallet and performance.

5. L5P (2017-present): The “Untunable” Engine

The latest Duramax is the most powerful and reliable yet, but it brings a new frustration.

The “Problem”:

- Encrypted ECM (Engine Control Module) prevents tuning

- No significant mechanical issues, but lack of customization

Impact on American Owners:

In a culture where truck modification is almost a rite of passage, especially in states like Colorado or Utah with their elevation challenges, the inability to tune the L5P for more power or better fuel economy has been met with disappointment.

6. Universal Duramax Issues

Some problems span across generations:

1. Allison Transmission Concerns:

- Torque converter shudder

- Harsh shifting

- Fluid leaks

2. Water Pump Failures:

- Bearing failures

- Coolant leaks

- Often occurs around 100k miles

3. Glow Plug and Glow Plug Controller Issues:

- More prevalent in colder states like Minnesota

- Leads to hard starts in winter

4. Cracked Pistons (Especially LBZ):

- Over-zealous tuning or extended high-load use

- Result: catastrophic engine failure

5. Oil Leaks:

- Valve cover gaskets

- Oil cooler lines

- Front engine seals

Preventive Measures for American Duramax Owners

- Use quality diesel fuel, especially in rural areas.

- Maintain a strict oil change schedule (critical for injector health).

- Monitor temps when towing, especially in hot climates.

- Be cautious with tunes; respect the engine’s limits.

- In cold states, use block heaters and quality glow plugs.

- Don’t ignore emissions system warnings.

- If deleting, understand the legal risks (and maybe reconsider).

The American Duramax Experience

The 6.6L Duramax journey reflects broader themes in American trucking culture:

- The tension between power and reliability

- The impact of emissions regulations on performance

- The DIY spirit (many owners become adept at repairs)

- Regional challenges (fuel quality, climate, elevation)

Despite its issues, the Duramax has a strong following. Why? Because when it’s running right, it embodies what American truck owners value: strength, endurance, and the ability to work hard day in, day out.

Each generation taught lessons:

- LB7: The importance of quality components

- LLY: Never underestimate heat

- LBZ/LMM: Fuel matters

- LML: Emissions are here to stay

- L5P: Sometimes, the factory knows best

For those considering a used Duramax, this guide should help you spot potential issues. For current owners, it’s a roadmap to longer engine life. And for all, it’s a testament to the ever-evolving world of American diesel trucks.

Also Read:

- Tundra Engine Problems: A Comprehensive Guide for Toyota Owners

- Ford 4.2L V6 Engine Problems: A Comprehensive Guide

- Ford 3.5L V6 EcoBoost Engine Problems: A Comprehensive Analysis

- Ford 5.4 Engine Problems: A Deep Dive into America’s Workhorse

Whether you’re hauling a fifth wheel through the Rockies, towing a boat down to the Gulf, or just rolling coal (not recommended) in rural Pennsylvania, understanding your Duramax is key. These engines have stories to tell—some triumphant, some cautionary. By learning from both, you ensure your 6.6L remains what it was built to be: a legendary workhorse in the great American landscape.

[…] The 6.6L Duramax Engine: A Deep Dive into Common Problems […]